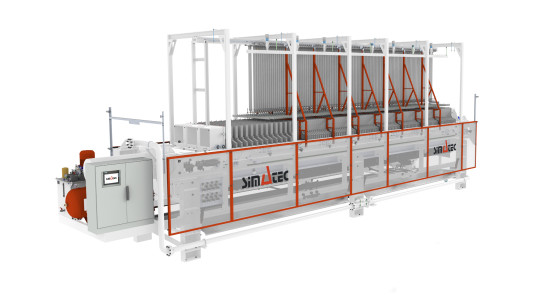

Simatec chamber filter press KFP-AK

Filter performance with system – side carrier meets cake discharge reliability

With the KAS system, Simatec has developed advanced technology for optimizing cake discharge in chamber filter presses. It is specifically designed for applications where conventional discharge methods reach their limits – for example, with highly adhesive or moist filter cakes and difficult discharge conditions.

The system has a modular design and can be used on all side carrier models – regardless of press size or plate type. It is suitable for both new systems and for retrofitting existing presses.

At its core is a series of precisely controlled pneumatic cylinders above the plate pack. These are connected to mechanical elements that actively support each filter plate and the associated filter cloth during the opening process. This reduces the adhesion between the cloth and the plate surface and facilitates the removal of the cake – even with low dead weight or high moisture content.

Depending on the process requirements, two operating modes are available:

- KAS in active mode: This mode is used when the cake adheres strongly and does not fall out on its own. The pneumatic holding cylinders actively push the cloths downwards and break the adhesion between the filter cake, cloth and plate. This allows the chamber to be completely emptied.

- KAS in passive mode: Suitable for brittle or deformable cakes that could become jammed during unloading. Here, the holding cylinders merely serve as a holding device for the filter cloths, which move with the sliding filter cake. This prevents jamming and supports gentle discharge.

The combination of mechanical support, intelligent control and adaptable operation makes the KAS system a reliable solution for automated cake discharge – even under difficult conditions. It minimizes downtime, increases operational reliability and sustainably improves the efficiency of the entire plant.