Important Preparatory Work for the Second Gotthard Tube at the South Access Gallery

The second Gotthard road tube will be constructed over the next few years. Since the beginning of 2021, the Marti Group has been hard at work on access tunnel 343, the Gotthard South access gallery at the South Portal in Airolo. The tunnel boring machine reached 2,000 m in February 2023, and tunneling operations will have reached 5,000 m by the summer.

Since 1980, the Gotthard Road Tunnel between Göschenen and Airolo has been operating as a national road link and is in need of extensive rehabilitation. A second tunnel tube is to be built for this purpose over the next few years. In the fall of 2022, the Marti Group received the definitive contract for lot 341, the construction of the south main tunnel. This batch of work includes excavation of the new road tunnel over a length of approximately 7.8 km as well as additional excavation of a southern fault zone. Marti has also been awarded lot 111, which includes materials management and logistics for North and South. Preliminary work has already begun on both batches of work.

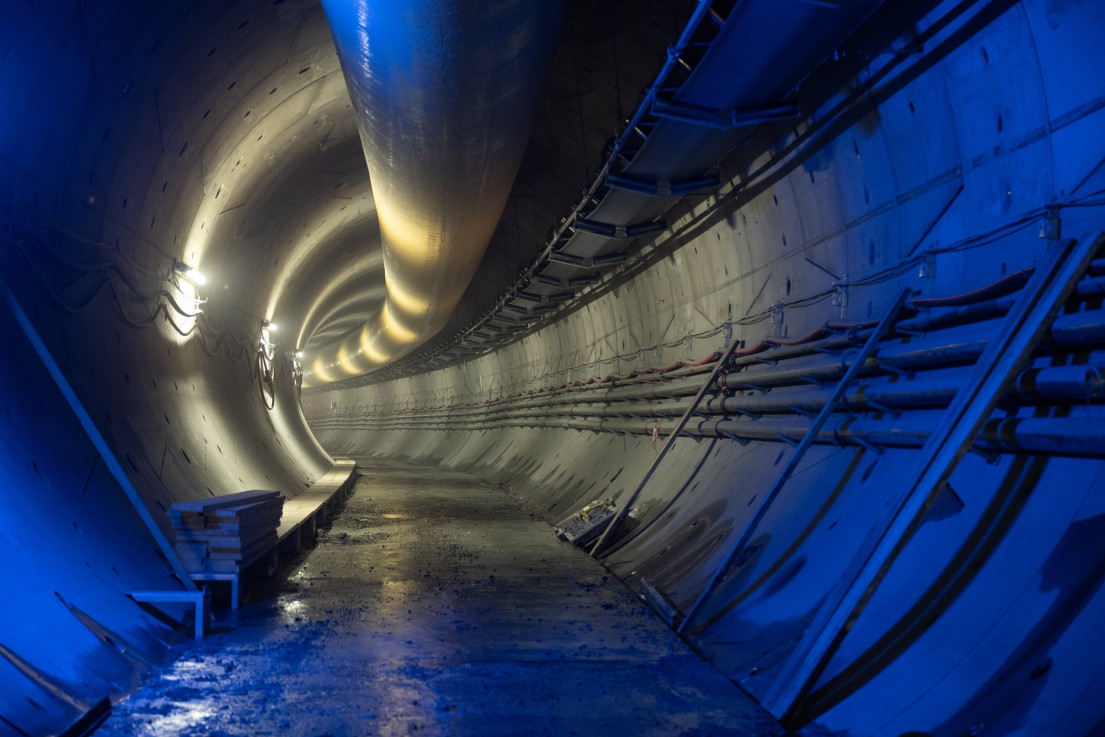

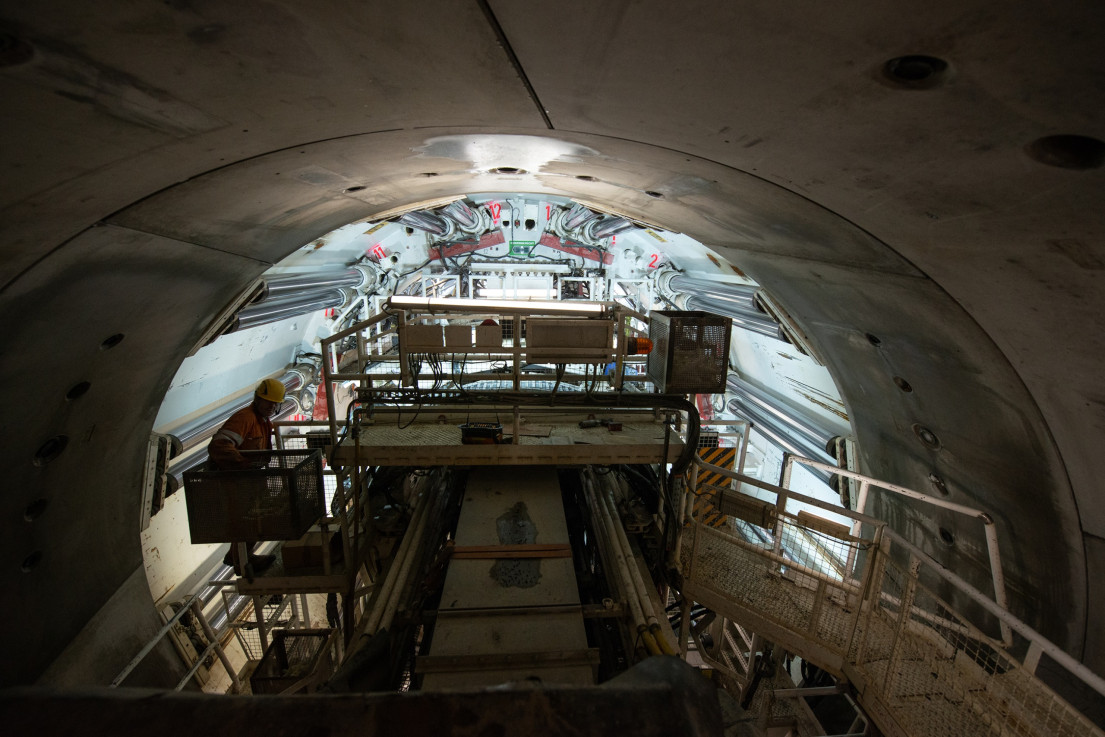

Lot 343, the Gotthard South access gallery on which Marti has been working since 2021, is also part of the overall Second Gotthard Tube project. In this case, a tunnel boring machine (with a diameter of 7.42 m) has been working its way northward to the geological fault zone mentioned above, known as the “Guspis zone,” since the summer of 2022. This zone is located in the mountains about 5 km from the South Portal in Airolo and will subsequently be crossed and secured as part of main batch of work 341. This makes it possible for the large tunnel boring machine (with a diameter of 12.39 m) of the main lot to subsequently cross the zone without any complications. After completion and commissioning of the road tunnel, the access gallery will be used as a ventilation and drainage gallery.

Status as of mid-December 2022

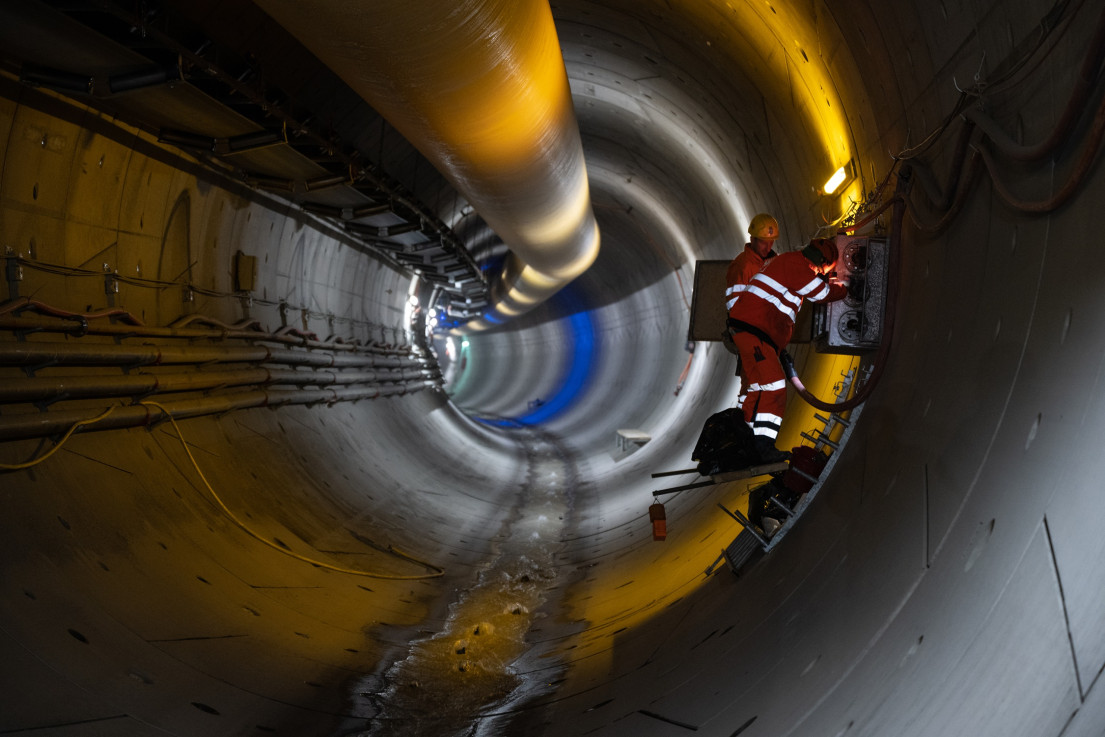

At this point in time, the tunnel boring machine (TBM) is engaged in tunneling operations at around 1,250 m. It already crossed the existing tube of the Gotthard Tunnel, putting it in a slightly sloping section (approx. 0.5%) until it is at the level of the future road tunnel. The tunnel is lined from end to end with concrete ring components, known as segmental rings, in single-shell construction. These rings will remain visible upon completion of the project. The Marti Tunnel crew uses an erector to position the segmental rings in the rear part of the shield of the ingeniously engineered TBM. After each tunneling stroke of 1.8 m in length, the crew members insert a complete tunnel ring consisting of six segmental ring components. Each day, the experienced team is installing an average of 60 of these components, corresponding to tunneling operations of 18 m. In parallel with the tunneling operations, the miners are installing a floor in the tunnel behind the TBM. A Marti Technik traversing bridge is used here to ensure that there is no interruption to the logistics of the machine, which is continuously supplied with segmental rings.

This construction site is particularly fascinating because you get to experience a wide range of tunneling work in a very brief period of time

Segmental ring production in in-house plant

The segmental rings for the Gotthard access gallery are currently being manufactured as quickly as possible at the Marti segmental ring plant at Klus near Balsthal. Some 7,000 of a total of 16,500 components have been completed as of the beginning of December 2022. “At the moment we are working in three shifts and producing between 27 and 30 components per shift,” explains Oskar Gisler, the Segmental Ring Production Manager. The segmental rings are transported by rail. Twice a week, a 13-car train delivers 26 complete tunnel rings directly from Klus to Airolo. These two trips make it possible to transport a total of 336 components to Ticino per week. A third trip per week will be added in early 2023.

Back in the South access gallery

“We are dealing with widely variable and challenging geological conditions here,” reports Nicole Kölbener, Production Manager for Driving Operations at the construction site. Weak rock and the resulting instability of the working face made steering the TBM difficult at times. Various work steps are carried out simultaneously, a circumstance that requires complex planning. Starting in January, in addition to the ongoing TBM tunneling operations and the concrete construction of the floor behind it, the logistics niches are to be constructed using blasting.